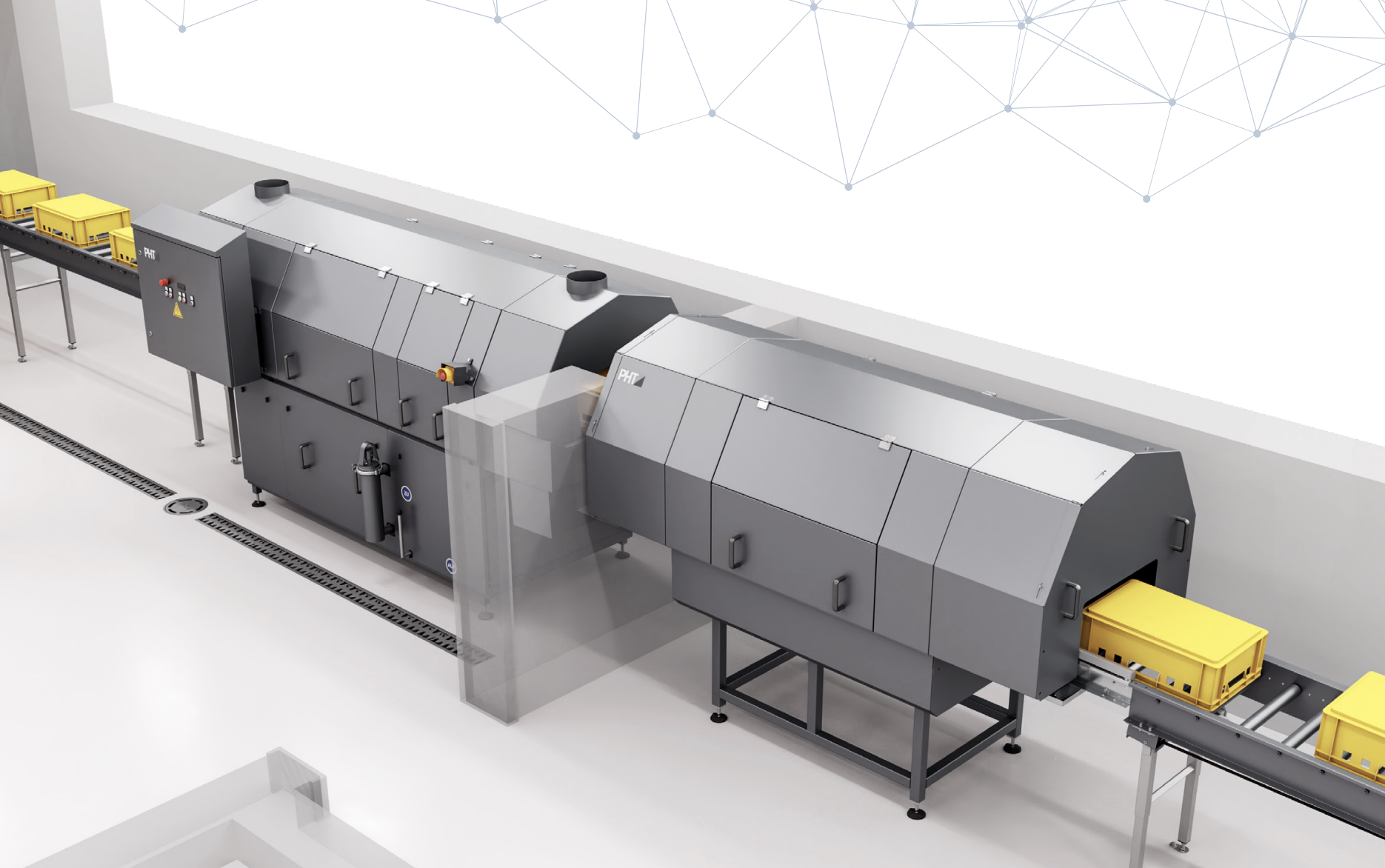

5 reasons for crate washers

Whether crates or other containers – hygienically perfect cleaning is crucial for food safety. The crate washer is indispensable tools for this. Five reasons in favour of crate washers:

1. Food safety

Crate washers efficiently remove food residues, contamination and germs that could affect the quality of the products. Thanks to the special nozzle arrangement of the PHT crate washers, even corners are cleaned and disinfected quickly and safely. The systems are designed to optimise the interaction of chemicals (cleaning agents), mechanics, temperature, water quantity and cleaning time in accordance with Sinner’s circle. Food is stored safely.

2. Hygiene regulations

Compliance with hygiene regulations is a legal requirement in the food industry. Crate washers help to fulfil these norms and standards. PHT crate washers clean crates and containers in accordance with the required cleanliness standards and can be considered as part of an HACCP concept.

3. Efficiency and costs of crate washer

Manual cleaning of crates and containers is time-consuming and labour-intensive. Crate washers automate the cleaning process. This leads to a considerable increase in cleaning speed. At the same time, labour costs are reduced. PHT crate washers are designed in such a way that even containers of different sizes can be loaded and unloaded quickly. For example, the PHT CM series washers allow crates of different heights to be washed unsorted. This means, for example, that the washing machines can clean Large containers, stackable crates, food-safe bins, ingredient boxes, transport crates and other containers such as e-crates. This makes it worthwhile even for small and medium-sized companies.

4. Reduced media consumption

Crate washers from PHT require little water and detergent – with 100 per cent cleaning performance. The design of the crate washers, their module sizes and the adjustment options are decisive for this. The module sizes and zone lengths are perfectly harmonised. The cleverly positioned cleaning rotor nozzles allow the containers to be set at an angle. Each crate corner is cleaned and disinfected to the required intensity. Coarse pre-rinsing and individually adjustable soaking times also ensure reduced media consumption. There is also no need for hygienically questionable separating curtains. These measures contribute to sustainability and minimise the ecological footprint of the cleaning processes.

5. Extended service life of the crates

The crate washers clean the crates gently. The service life of the crates and containers is extended. This saves costs for replacing dirty or damaged crates in the long term.

The PHT Group offers crate washers in various sizes and for different requirements. Find out more about the efficient use of crate washers. We will find the solution that is exactly right for your food business.