Access control in food production: Why controlled access is the basis for safe food

In food production, seconds often determine hygiene or contamination. An employee who skips hand disinfection in the rush of a shift change can unknowingly carry millions of germs into the production area. Access controls in food production are therefore not an optional extra, but a critical control point in the HACCP concept that protects consumer health and safeguards companies from serious consequences.

Why do food businesses need access control?

Humans as the greatest source of contamination: The human body provides ideal conditions for the proliferation of germs: it is warm and moist. Humans harbor a variety of microorganisms, including streptococci, staphylococci, and intestinal bacteria such as salmonella, shigella, and Escherichia coli. We transmit most germs with our hands. An unwashed hand is colonized by around ten million germs.

These germs originate from everyday environments outside of production: public transportation, door handles, cell phones, cash. Without effective entry controls, these microorganisms come into direct contact with food and production equipment. Even with existing hygiene regulations, practice shows that in the hectic day-to-day operations, rules are not always carefully followed despite all the training and instruction.

The consequences of inadequate access control

The consequences of inadequate personal hygiene can be dramatic: foodborne illnesses endanger consumer health and can be life-threatening in severe cases. For companies, contamination means product recalls costing millions, lasting damage to their image and, in the worst case, closure of their operations by food safety authorities.

A single hygiene incident can undo years of brand building. In the age of social media, negative news spreads rapidly. Investing in professional access control systems is therefore not a question of cost, but a matter of securing the company’s existence.

HACCP as a legal obligation

Since EU Regulation 852/2004 came into force, the application of HACCP principles has been mandatory for all food business operators in the European Union. HACCP stands for Hazard Analysis and Critical Control Points and describes a systematic concept for identifying, evaluating, and controlling hazards in food production. Access to production areas represents one such critical control point.

The HACCP system requires companies to analyze potential hazards and establish measures to control them. Uncontrolled access by personnel to hygiene-sensitive areas is one such potential hazard. A documented, traceable access control system fulfills this requirement and at the same time provides the necessary evidence for official inspections.

How does modern access control work?

The principle of forced guidance

Professional entry controls work on the principle of forced guidance. Access to the production area is physically blocked by a turnstile or airlock. This only allows passage once all the required hygiene steps have been verifiably completed.

With the PHT EntryX entry control system, for example, tamper-proof nozzle positioning ensures that hands are optimally moistened with disinfectant or soap. Only after correct application does the motor-driven turnstile start gently and allow passage. It is technically impossible to skip or bypass this process.

Sensor-controlled operation

Modern systems are fully sensor-controlled and therefore contactless. This not only reduces the risk of contamination from surfaces, but also increases acceptance among employees. The intuitive operation requires no extensive training and works independently of language skills.

Step-by-step visualization via integrated LEDs, such as those offered by the PHT EntryX Plus entry control system, guides the user safely through the entire hygiene process. This eliminates potential errors in use from the outset.

Entrance control with integrated sole cleaning

While hand hygiene is established practice at most entry points, sole cleaning is often neglected. Yet dirty shoe soles are one of the main causes of cross-contamination in food production. Parking lots, changing rooms, sanitary areas—microorganisms accumulate everywhere and are carried into hygiene-sensitive areas with every step.

Modern hygiene locks solve this problem elegantly: while the employee disinfects their hands, the soles of their shoes are cleaned and disinfected at the same time. Rotating brushes mechanically remove dirt, while disinfectants kill germs. The PHT hygiene stations of the SoleX series combine both functions in one compact unit. Activation is contactless via capacitive sensors in the handrail, which also ensures a secure footing. Self-cleaning brushes and tool-free maintenance minimize the amount of care required. During shift changes, the systems process several people per minute. Sole cleaning does not become a bottleneck, but a natural part of the hygiene process.

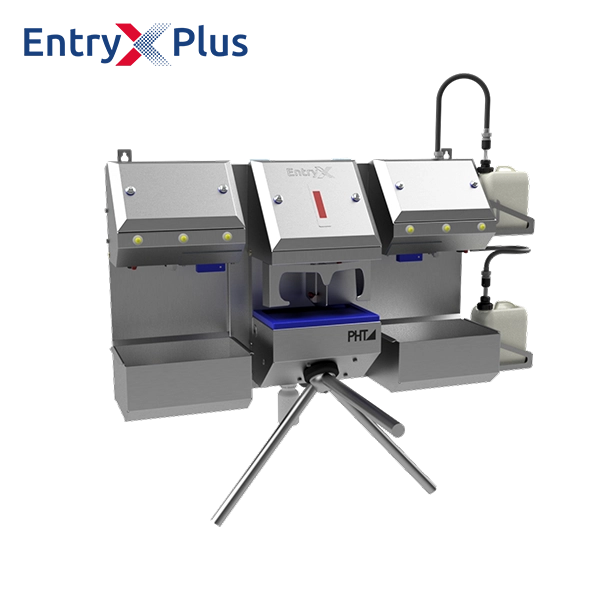

EntryX entry control

The PHT EntryX access control system is part of the InnovationX series and was developed specifically for the demanding requirements of hygiene-sensitive areas. The system is made entirely of stainless steel and has smooth, germ-resistant surfaces that enable thorough cleaning.

The tamper-proof nozzle positioning ensures optimal wetting with disinfectant or soap. The motor-driven turnstile starts gently and prevents unauthorized passage. The transparent dispenser area allows for easy cleaning and maintenance, while the individually adjustable operating position ensures ergonomic operation.

The EntryX comes standard with an LED empty indicator that provides timely notification when disinfectant is running low. The specially corrosion-protected drive block guarantees durability even with intensive use. The service-friendly housing with hinged turnstile unit and removable cover makes maintenance work much easier.

EntryX Plus entry control

For businesses with increased requirements, the EntryX Plus entry control system offers an advanced solution. The guided, combined hand cleaning and disinfection unit enables hygienically controlled access with a complete hygiene process.

The generously designed hand cleaning area is equipped with a sensor-controlled one-hand soap dispenser. Step-by-step visualization via integrated LEDs guides the user safely through the entire process. The motor-driven 3-arm turnstile only allows passage when used correctly.

Supplementary hygiene solutions

For a comprehensive hygiene concept, the PHT Group offers additional components that can be seamlessly integrated into access control systems. The modular HeliX hygiene stations enable additional disinfection options at strategic points in the workplace. Sole cleaning devices and floor drainage systems complete the concept.

The WashX hand cleaning channels with sensor control are ideal for areas where intensive hand cleaning is required. The hygienic stainless steel construction without dead spaces and the self-draining geometry prevent water accumulation, which could serve as a breeding ground for microorganisms.

PHT Group: Your partner for professional access control in food production

The PHT Group specializes in state-of-the-art hygiene solutions for use in hygiene-sensitive industries such as the food industry. Our InnovationX series products have been designed by experts for experts and set new standards in terms of hygiene safety, ease of use, and serviceability.

From compact entry control systems to combined hand cleaning and

disinfection units to complete hygiene sluices, we offer the complete spectrum of modern hygiene technology from a single source. All systems are characterized by hygienic design, durable construction, and intuitive operation.

Benefit from our many years of expertise in the food industry. We develop tailor-made solutions for your specific requirements and accompany you from the initial needs analysis through planning to successful implementation.

Contact us now for an individual consultation and find out how our access control systems can sustainably improve the safety and efficiency of your food production. Together, we will develop the optimal hygiene concept for your business – so that you are well prepared for every audit and inspection.

Schedule a consultation now and discover professional access control solutions for your food production facility!