Automated foam cleaning: hygiene at the touch of a button with consistent quality

When it comes to hygiene, there can be no compromises in food production. Foam cleaning and disinfection are basic requirements for product safety, quality and compliance with legal regulations. At the same time, many companies face the challenge of making cleaning processes efficient, reliable and resource-saving.

Automated foam cleaning offers the ideal solution here: it combines state-of-the-art technology with simple operation and guarantees consistently high cleaning quality – regardless of time, personnel or production pressure.

Why foam cleaning is so versatile in food production

Automated foam cleaning systems can be used in almost all areas of food production – wherever hygiene is a top priority. Whether in large rooms, technical facilities or sensitive transition areas, this technology ensures clean and safe conditions.

Typical examples are conveyor belts that come into constant contact with food during everyday production, as well as entrances to production areas where germs or contamination must be reliably removed.

This flexibility makes automated foam cleaning an indispensable part of modern hygiene concepts.

Foam cleaning technology that impresses: clean solutions for the highest demands

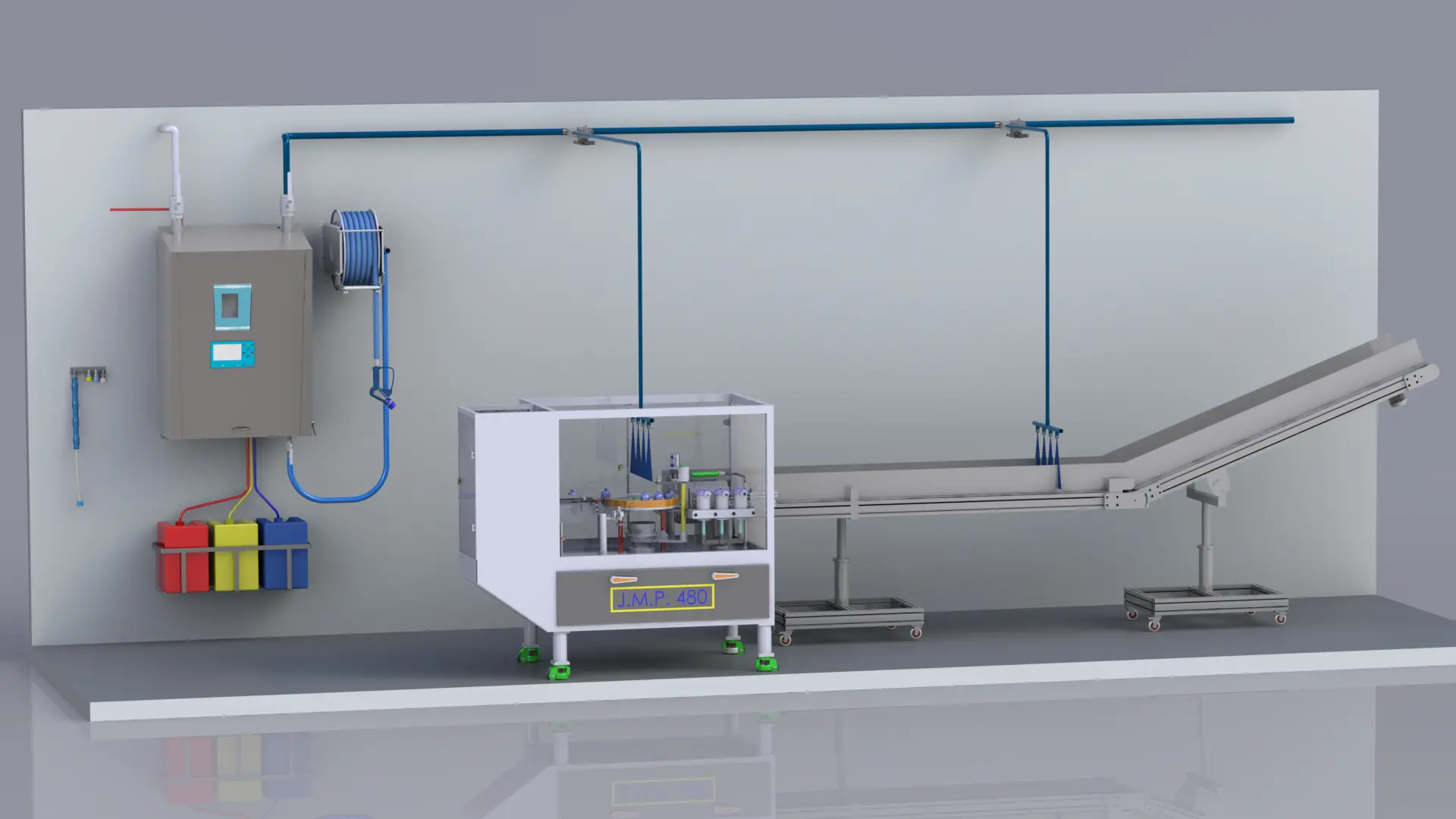

The PHT Group’s systems are designed to be powerful, user-friendly and efficient at the same time. At the heart of the system is the automatic station, which is supplied with a hose reel and control cabinet.

- Customised nozzle bars: These can be tailored precisely to the respective area of application. This enables them to rinse, foam and disinfect with maximum efficiency and uniform effect.

- Control cabinet: This is where the cleaning programmes are controlled. Businesses can store individual sequences so that each process is optimally tailored to their own hygiene requirements.

- Display on the pump: The clear display allows you to check the current values at any time. This gives those responsible full transparency over the cleaning process.

This combination of individual adaptability and technical precision ensures that cleaning processes are not only efficient, but also reliably reproducible.

Foam cleaning for consistently high quality – your decisive advantage

Automated foam cleaning is more than just a technical aid – it is an important component of comprehensive hygiene concepts. In combination with hygienic design, clear processes and other automation solutions, it raises the entire operation to a new level of safety and efficiency.

The modular systems from the PHT Group can be flexibly expanded and individually adapted. This makes them ideal for both new buildings and existing facilities, offering long-term investment security.

Conclusion: Cleanliness with a system

Automated foam cleaning ensures visible cleanliness, consistent results and maximum product safety – all with a significantly reduced workload. With state-of-the-art technology, customisation options and clear processes, the PHT Group helps food businesses raise their hygiene standards to a new level.