Industrial washing systems: Professional cleaning technology for food production

The PHT Group has over 30 years of experience in the development and manufacture of industrial washing systems for food production. Our engineers and technicians understand the specific challenges of different food sectors and develop customized solutions that are precisely tailored to your requirements. We analyze your specific requirements and develop the optimal cleaning solution for your business. In doing so, we take into account not only current needs, but also future developments and expansion possibilities.

From dairies and meat processing to beverage production, our industrial washing systems ensure the hygienic cleaning of Euro standard containers, transport crates, and production utensils in accordance with the highest standards.

What are industrial washing systems?

Industrial washing systems are specially developed large-scale cleaning systems for industrial use in food production. These highly specialized systems offer high performance, automation, and strict compliance with hygiene regulations.

Industrial washing systems handle large quantities of containers, crates, and production utensils per hour, ensuring consistent, reproducible cleaning quality. They are designed to reliably remove even stubborn product residues, fats, and proteins while protecting the sensitive surfaces of the containers.

The importance of washing systems in the food industry

The food industry is subject to strict legal requirements that mandate complete hygiene in all areas of production. Industrial washing systems play a central role in the fight against contamination and cross-contamination.

Even the smallest amount of contamination can have catastrophic consequences in industrial food production: product recalls costing millions, damage to reputation and, in the worst case, health risks for consumers. Professional industrial washing systems minimize these risks through systematic, verifiable cleaning processes.

Meat and sausage industry

Meat processing places particularly high demands on industrial washing systems. Protein residues and fats require specialized cleaning chemicals and high temperatures. PHT washing systems for the meat industry use multi-stage cleaning processes and can even reach hard-to-access areas in meat crates and containers.

Dairy and cheese production

Dairy products leave behind stubborn protein films that require special alkaline cleaners. Industrial washing systems for dairies must also be able to handle the typical milk containers of various sizes.

Bakery and pastry shop

Baked goods residues and dough residues pose other challenges. Industrial washing systems for bakeries are specialized in cleaning baking tins, baking sheets, and transport boxes and operate with customized cleaning cycles.

Beverage industry

Beverage production requires the highest standards of hygiene when cleaning bottles, crates, and production containers. Industrial washing systems must be able to handle different container sizes and materials.

Convenience and ready meals

The production of ready meals combines different food sectors and requires flexible cleaning systems that can handle different types of contamination.

PHT industrial washing systems: Technology for the highest demands

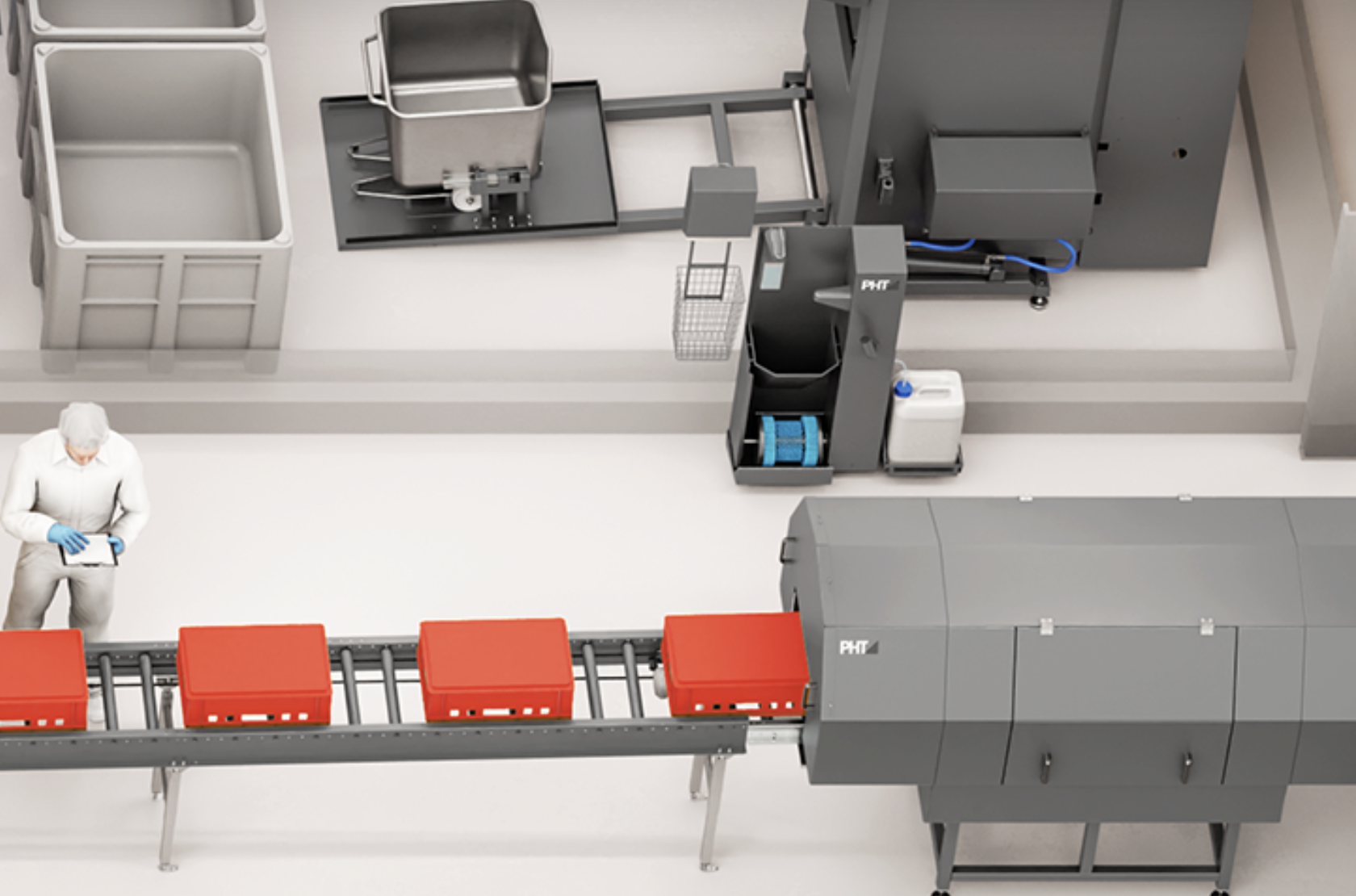

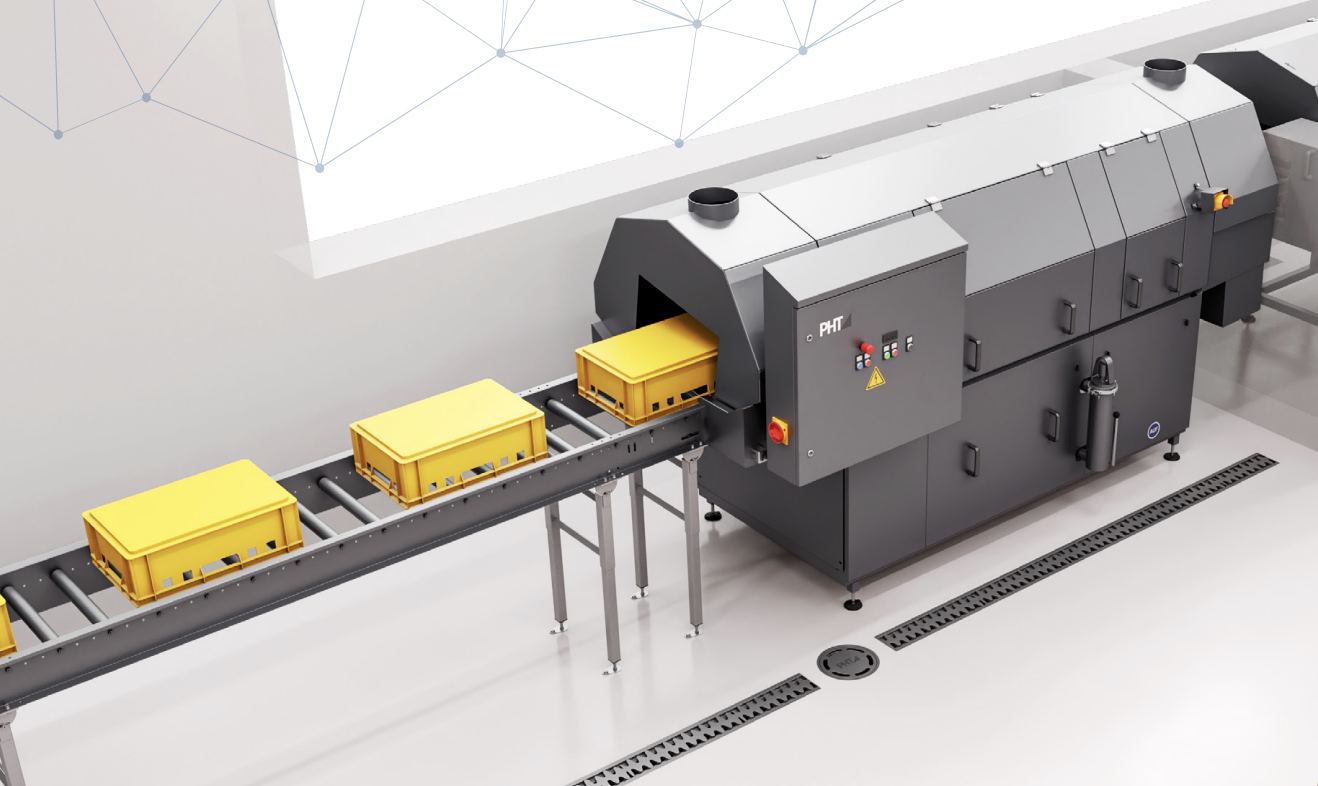

Continuous systems for large businesses

PHT continuous washing systems are the solution for large industrial companies with high throughput. These industrial washing systems process large quantities and operate fully automatically.

Automated conveyor technology continuously transports the containers through various cleaning zones. Multi-zone systems with pre-rinsing, main cleaning, rinsing, and disinfection ensure optimal results. Intelligent controls automatically adjust all parameters to the container type and degree of soiling.

Compact dishwashers for small and medium-sized businesses

PHT offers compact and powerful washing machines for medium-sized food producers. These systems combine industrial cleaning performance with a space-saving design.

- Rotor nozzle technology generates powerful water jets for optimal cleaning.

- Flexible loading allows different types of containers to be cleaned simultaneously.

- Modular design allows for later expansion as requirements increase.

Hygienic design as a basic principle

PHT offers compact solutions for smaller businesses with limited space. High-performance continuous systems for large industrial businesses. Special systems for specific requirements and container types. All PHT industrial washing systems consistently follow the principles of hygienic design:

- Dead space-free design prevents the accumulation of dirt and germs. Self-draining geometry eliminates standing water as a source of germs.

- Rounded edges and smooth surfaces make the system easy to clean.

- Fully stainless steel construction made from high-quality materials ensures corrosion resistance and durability.

- Automated self-cleaning without dismantling.

Invest in the future of your food production

Professional industrial washing systems from PHT are more than just cleaning systems—they are investments in the future of your company. The highest hygiene standards, optimized operating costs, and reliable compliance ensure your long-term success in the food industry. With PHT, you are investing in quality, reliability, and long-term partnership.

Contact us now for a free initial consultation and find out how our industrial washing system solutions can sustainably improve the hygiene and efficiency of your food production. Arrange a no-obligation consultation now.