Guard against Listeria with intelligent, holistic hygiene systems

Cases of illness, plant closure, dismissals, investigations for negligent homicide – these may be the results of Listeria contamination in a food production facility. Consumers’ safety has the highest priority and therefore prevention of contamination should be the order of the day for every food manufacturer.

How can a production facility be protected against Listeria contamination?

Listeria is a feared opponent in food production. This pathogenic germ can cause listeriosis in humans, which can have serious health consequences. Consumer safety should always be the top priority in the food industry and holistic hygiene concepts can help companies to better protect themselves against pathogen contamination.

Although only a small proportion of food recalls are due to Listeria contamination, these pathogenic bacteria pose a particularly serious health risk. Recalls due to Listeria usually concern unpasteurised milk and cheese and deli products such as sausages, cold meats and smoked fish, meat or poultry products, but chilled fruit and vegetable products can also be affected. Although Listeria are killed by heat treatment, potential recontamination is possible during further processing and cold storage.

Food manufacturers are responsible for placing only safe products on the market and which do not pose a risk to consumers within the normal sales period. Each production process has specific critical points during the workflow, which are recorded in the facility’s individual HACCP concept. However, the following points apply to all facilities to reduce the risk of Listeria contamination:

- Preventing Listeria being introduced into the facility

- Preventing product contamination

- Monitoring and control

- Decontamination in the case of Listeria detection

Modern hygiene technology as a protective shield for personnel and operations

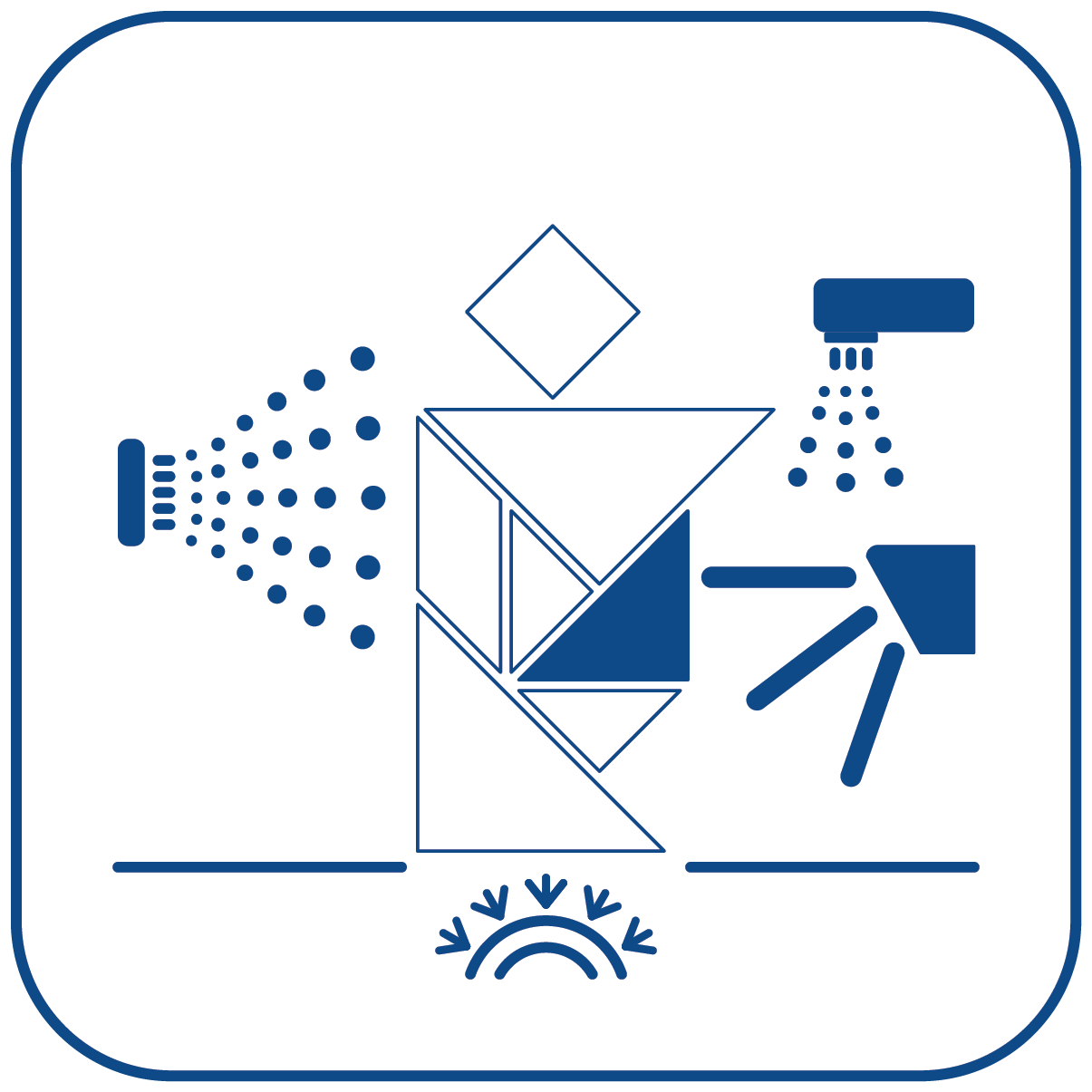

To minimise the risk, nothing should be left to chance when it comes to hygiene in a food production facility. Every employee in a food production facility poses a risk to the product. It is therefore necessary to invest in both knowledge and technology through employee training and installation of intelligent hygiene concepts that incorporate components such as:

- Hygiene lobbies and access control

- Hand cleaning and disinfection

- Sole cleaning and disinfection

- Cleaning and disinfection of equipment

Access to the production area is a particular risk point, specifically at the transition from an unclean to a clean area. A professional hygiene lobby is recommended here, because it ensures that hands and soles are disinfected automatically and in a controlled and time-efficient manner. The turnstile grants access to the production area only once an employee has passed through the lobby and performed all the cleaning steps correctly.

Special control mechanisms ensure additional safety. For example, visual monitoring of hand disinfection practically prevents incorrect use. With the MANO Vision disinfectant dispenser, a camera monitors whether both hands are held in the detection area and in an optimal position for disinfection. The disinfectant is dispensed only if the fingers are spread apart in the spray area. The user can see the correct position of the hands on the display. The turnstile grants access to the production area only after the hands have been disinfected. Such visual monitoring largely excludes manipulation of the disinfection process.

Facility hygiene with low-pressure foam cleaning

Safe cleaning and disinfection solutions are available for the facility itself. Low-pressure foam cleaning is recommended for surfaces because it is effective, economical and time efficient. Both acidic and alkaline cleaning agents can be used, and the applicable option is selected simply by toggling a lever. Switching between water and foam is just as easy and the operator simply selects the desired application on the device. Rinsing, foam and cleaning nozzles allow for customising the respective cleaning steps to ensure comprehensive hygiene.

Customised, holistic hygiene concepts from the market leader

PHT is the market leader for complete hygiene systems in the food industry. PHT develops state-of-the-art solutions that take individual needs into account. We offer our high-tech hygiene solutions as a modular system to create an appropriate, holistic hygiene concept for every customer, and we place great emphasis on providing advice and technical support.

Get in touch with us to find out what the best hygiene solution would be for your facility. Contact us.