Hygiene equipment for the food industry

It is clear that anyone who wants to bring food into circulation must fulfil the highest hygiene requirements and needs for hygiene equipment. Consumers must not be exposed to any health risks. Legal standards regulate hygiene requirements. Good hygiene equipment helps to fulfil the standards. Our hygiene technology makes a valuable contribution across all process stages of food production – from the start of operation and production itself to the cleaning of consumer goods and the plant.

Preventive hygiene equipment

Prophylaxis is the best form of hygiene protection. In other words, it is easier and safer to prevent germs, bacteria and other pathogens from entering the production facility in the first place. Preventive hygiene equipment covers two areas: The sanitary rooms and access to production. In the sanitary rooms, easy-to-clean social room equipment supports the hygiene process. This includes cabinets based on the clean-unclean principle, changing room lockers, panels for boots and clogs, storage systems and disinfectant dispensers.

Before entering the production facilities, cleaning and disinfecting hands and, if necessary, boots and soles is a matter of course. Our controls and hygiene sluices therefore ensure hygienic access with hygiene equipment to the production area. And: The company should be generously equipped with disinfectant dispensers.

Customised cleaning systems

You can clean production areas and work equipment efficiently with our low-pressure foam cleaning system together with our floor drainage concepts for the drainage area of cleaning machines and production facilities. Our systems are easy to use, offer a high level of work and hygiene safety and adapt to your work processes.

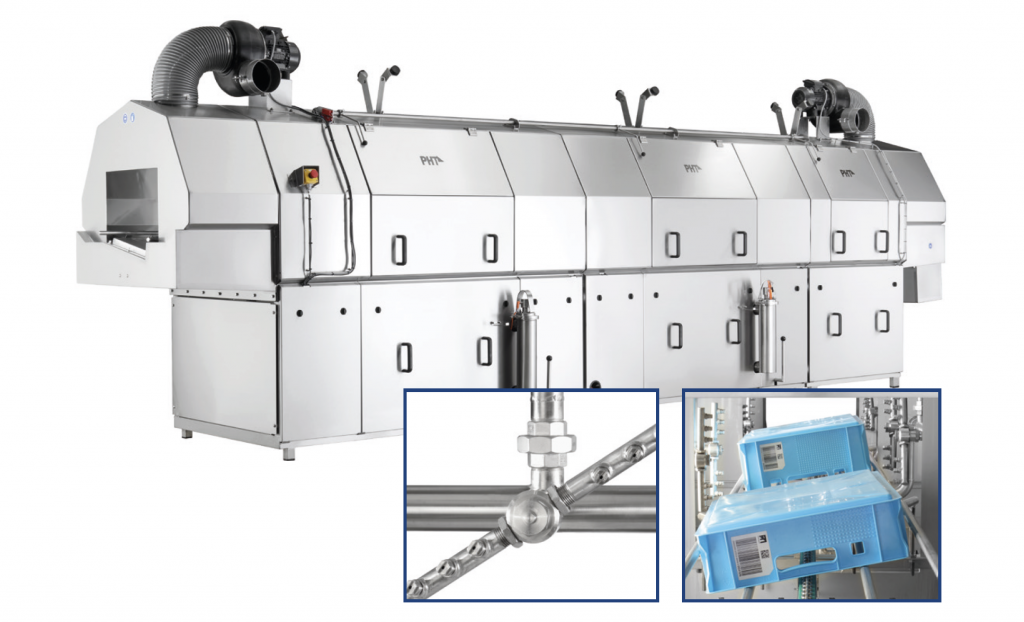

Cleaning machines and container cleaners for your accessories are just as important. Our automated cleaning machines not only reliably clean your work equipment, but also pose no hygiene risk themselves – and work economically at the same time. This means that they use water, cleaning agents and energy sparingly while maximising cleaning performance.

Hygienic transport

Of course, hygienic transport should not be neglected. Our hygiene equipment also helps here. Our crate cleaning machines, container cleaning systems and cleaning systems for lifting and loading trolleys clean and disinfect the transport boxes safely with low media consumption.

Hygiene control in catering and food businesses: Essential measures

Clean-unclean separation: Everyday and work clothes are strictly separated, e.g. by special lockers, shoe and boot storage systems, containers for dirty laundry, etc.

Shadow boards: Shadow boards are a simple form of separating work equipment in accordance with the GFSI standard. They ensure hygienic separation of work equipment by means of colour coding.

Access controls: Employees only enter the production facility and the kitchen after cleaning has been completed. This is ensured by turnstiles with an upstream hygiene station or washbasin.

Hand and sole disinfection: Washbasins and disinfectant dispensers or even a complete hygiene station with sole cleaning are located in front of all access points to the production area.

Floor cleanliness: Another method of reducing the introduction of dirt is so-called hygienic floor systems, which are tubs with brush modules embedded in the floor. It is equally important to avoid standing water or to remove it quickly. Scrapers, for example, help with this.

We support you in keeping an eye on important aspects of hygiene and food safety. Our high-performance hygiene equipment covers the entire production process. Get in touch with us.