5 essential tips for hygienic change room equipment in food production

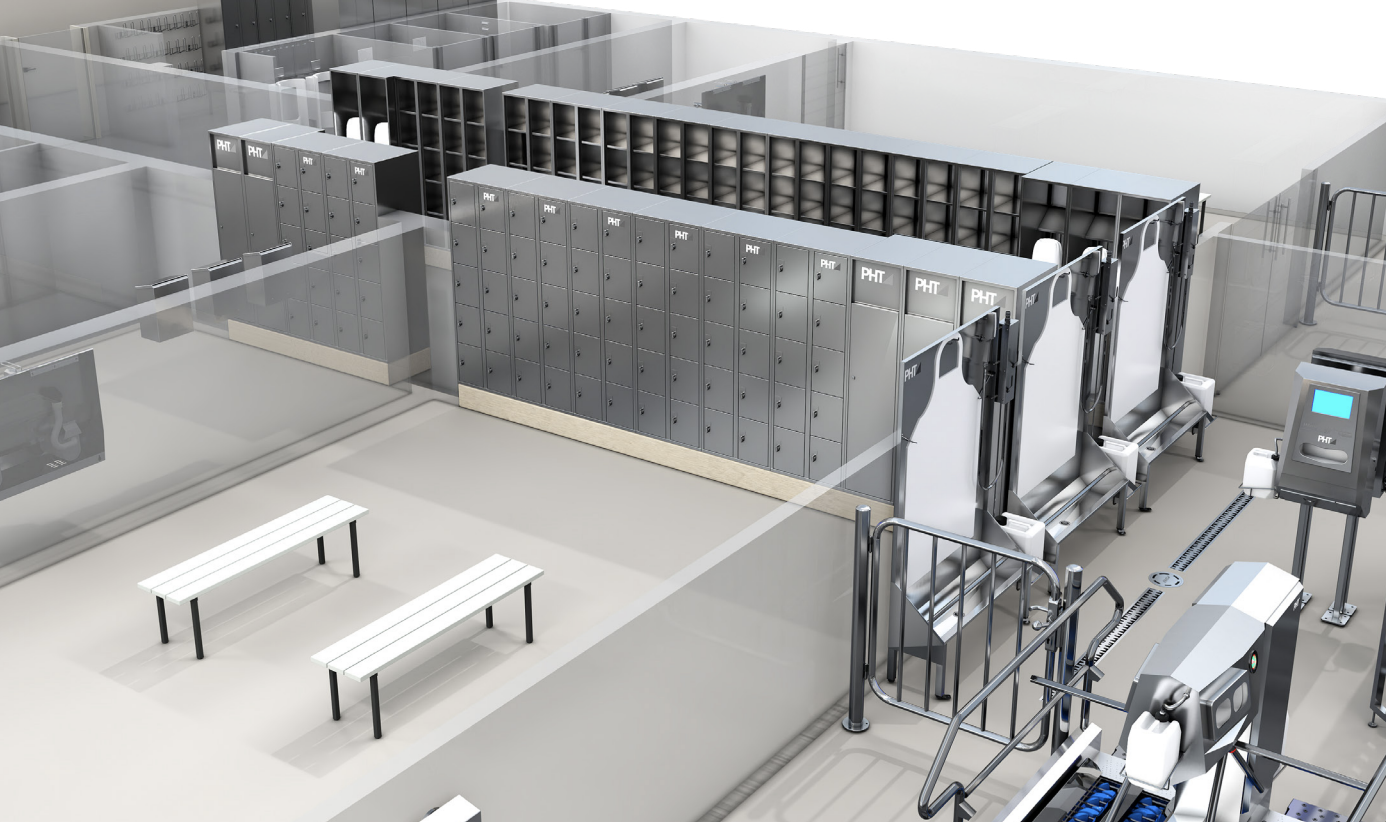

A well-designed change room is essential for food producers. Internal personnel hygiene begins in the change room. This is because the change room is the interface between the hygienically risky outside world and hygienic production.

These five points are part of any social space planning within the HACCP concept:

1. Intelligent change room equipment

- Wardrobe lockers and storage compartments: Ensure hygienic storage of your employees’ work clothes and personal belongings. Wardrobe lockers with ventilation slots and sloping roofs prevent dirt from accumulating. A clean/unclean separation within the lockers and shelves ensures that dirty street clothes do not come into contact with clean work clothes.

- Shoe storage and drying: Special storage systems for shoes and boots help to keep shoes dry and clean. This minimises the risk of mould and fungal growth.

2. Consistent hand cleaning and sole cleaning

- Touchless hand wash basins: Provide sufficient hand wash basins. The basins and hand dryers should be intuitive and contactless to operate.

- Automatic hand disinfection: Install sufficient hand sanitiser dispensers in communal areas and corridors. These should be equipped with sensors to enable touch-free use.

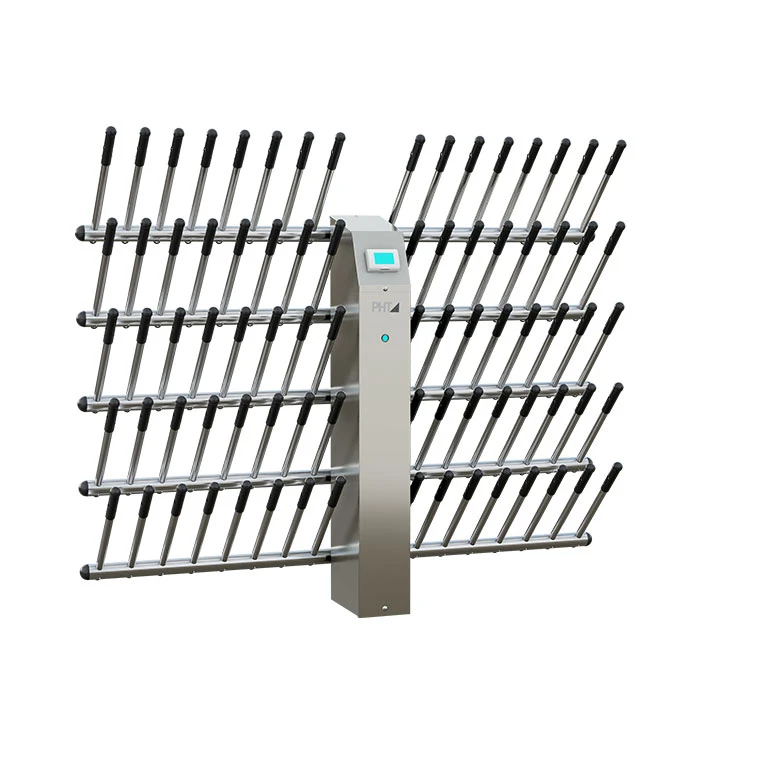

- Sole cleaning devices: Use sole brushes with special technologies to thoroughly clean and disinfect your employees’ soles and boot shafts.

3. Access controls to critical areas

- Hygiene Stations: Equip access to critical areas with hygiene stations that combine hand and sole cleaning.

- Forced guidance: Guide your staff through unavoidable and controlled hygiene stations. This ensures that all cleaning and disinfection steps are followed.

4. Process reliability and user-friendliness

- Guided processes: Implement systems that give staff clear instructions and structure the hygiene process. This reduces errors and ensures compliance with hygiene protocols.

- Easy maintenance and appliance cleaning: Make sure that all hygiene techniques and equipment are easy to clean and maintain. This contributes to smooth operation.

5. Regular training courses

- Hygiene training: Train your staff regularly in the latest hygiene practices and the correct use of hygiene equipment. This promotes awareness of the importance of hygiene and the correct use of the systems in place.

Optimised change room equipment combines modern hygiene technology, structured processes and hygiene-sensitive employees. Creating clear guidelines and structures significantly increases production safety in food manufacturing. We will be happy to advise you on social room design and optimisation.